What is the Difference Between Tempered Glass and Standard Glass?

Tempered glass and standard (annealed) glass differ mainly in how they are processed and how they respond to stress and breakage.

Manufacturing Process

All glass begins with a similar base: sand, soda ash, and lime are melted at high temperatures and formed into shape by blowing, pressing, or drawing. Once shaped, the glass undergoes a cooling process called annealing, which relieves internal stresses and helps prevent spontaneous breakage.

The key difference lies in how the glass is cooled:

-

Standard glass is cooled slowly in a controlled environment, resulting in a relatively soft and easily breakable material.

-

Tempered glass is reheated and then rapidly cooled using high-velocity air. This quick cooling process significantly increases its strength—making it about four times stronger than standard glass.

Breakage Behavior

One of the most visible differences is how each type of glass breaks:

-

Standard glass fractures into large, sharp, jagged shards that pose a high risk of injury.

-

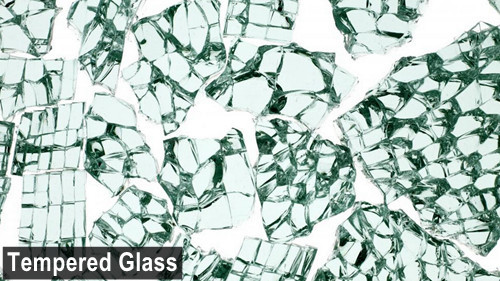

Tempered glass shatters into small, blunt, pebble-like pieces that are much safer to handle.

Impact and Safety

-

Standard glass may only break at the point of impact, leaving the rest of the pane intact. This characteristic can provide some degree of security.

-

Tempered glass, while more impact-resistant, shatters entirely when broken. This makes it ideal for applications where safety is a priority, such as shower screens, sliding doors, glass railings, and car side windows.

Heat and Scratch Resistance

Tempered glass is more resistant to heat and surface scratches than standard glass, making it more suitable for environments where high temperatures or wear-and-tear are expected.

Workability

-

Standard glass can be cut, drilled, or shaped after production.

-

Tempered glass, once processed, cannot be altered. Cutting or drilling it will cause it to shatter.

Tempered vs. Laminated Glass

While tempered glass used to be the go-to for safety glazing, laminated glass is now often preferred in high-safety applications such as car windshields. Laminated glass consists of two layers of glass bonded with a plastic interlayer. When broken, it cracks but remains in place—offering better protection from penetration and injury.